PDS

Versatile and Compact Unit with unique 180° Tie-Rod Swing Action

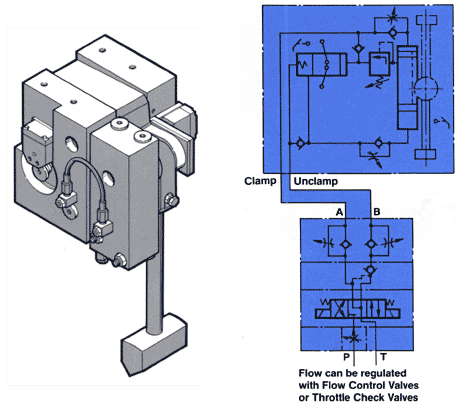

The PDS unit offers Optima's toggle system in a compact and versatile form. Clamp force is generated mechanically after being hydraulically activated. In the clamped position the unit is mechanically locked and fail-safe.

The unit also incorporates Optima's unique "Activator" system. This system allows the clamp to monitor clamping force, tie-rod failures, die or platten deformations, as well as any changes along the clamp line. Any irregularities will result in an immediate press shutdown.

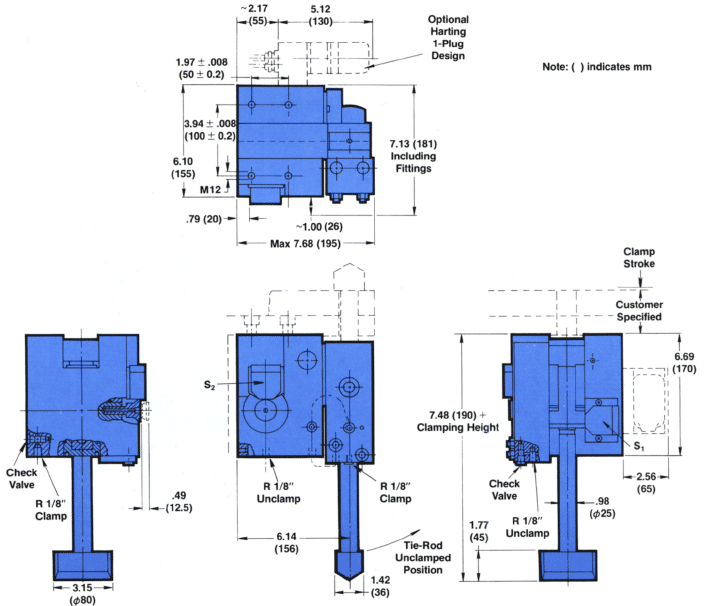

Due to its design and the unique 180° swing radius of the tie-rod, the unit completely disappears from the platten surface. This allows dies or bolsters to be brought in from any direction.

Features

- 1800 swing tie-rod.

- Compact size.

- Unique application possibilities.

- Hydraulically activated mechanical clamping.

Technical Data

| PDS 6.3 | PDS 10 | ||

| Clamp Force | tons | 7 | 11 |

| Setting Pressure | psi | 1300 | 1450 |

| Holding Capacity | tons | 11 | 16 |

| Operating Pressure (min.) | psi | 1600 | 1750 |

| Operating Pressure (max.) | psi | 2000 | 2000 |

| Clamping Stroke | inches (mm) | 0.18 (4.5) | 0.14 (3.5) |

| Clamping Tolerance | inches (mm) | ±.008 (±O.2) | ±.008 (±O.2) |

| Tie-Rod Swing Angle (adjustable) | 180° | 180° | |

| Oil Volume per Event (Clamp) | in3 | 2.4 | 2.4 |

| Oil Volume per Event (Unclamp) | in3 | 2.4 | 2.4 |

| Oil Flow Require per Unit* | gal/min | 0.1 -.15 | 0.1 -.15 |

Hydraulic Fluid H-LP Viscosity = 25-60 cST / 40° C. Filter = 20-25 µm

*If a pump with a greater flow volume than necessary is used, the flow must be throttled.