OSV

Slide Lock System

Area of application

The Optima slide lock system type OSV is used for rendering the slide safe when working in the die space or on the machine itself. It is mainly used for mechanical, but also for hydraulic presses.

Rigidly installed, suspended in the press crown area, its use requires a slide which has externally welded-on contour plates, or cut-outs in the slide.

Mode of operation

By means of an electric motor and a gearbox, a threaded nut is set in rotation. The nut, in cooperation with the associated spindle, initiates the necessary rotary movement. The tie rod, which is in the parked position (fully extended), first performs a 90° rotation, and then moves directly to the slide and prevents it from being lowered accidentally.

A hydraulic cushion ensures release of the tie rod, even under load (within the possible release distance). Sticking of the tie rod is thus virtually impossible.

Movement sequence for securing the slide:

- 90° rotation of the tie rod into the locking position

- Movement of the tie rod to the underside of the slide (release of the slide in reverse order)

Distinguishing features

Due to the continuous variation in length of the tie rod, the press slide can be locked in any position. The single-motor construction ensures simple electrical installation and compact external dimensions.

Electrical control of the following functions (switches):

- Tie rod extended (slide free) (S1, inductive)

- Tie rod rotated into slide secure position (S2, inductive)

- Slide secured (S3, mechanical)

Technical Data

| Motor: | DC motor |

| Supply voltage: | 460 V, 60 Hz; S3- duty factor 15% |

| Wiring plug: | Harting-plug connection HAN 3HvE* |

| Switches: | 2 inductive proximity switches p-n-p normally open contact |

| Supply voltage: | 10-30 V DC |

| Wiring plug: | Harting-plug connection HAN 25 D* |

| Switches: | 1 mechanical limit switch 1 normally closed contact separated according to VDE 0113 1 normally open contact |

| Valve: | 24 V DC; 1.1A |

| Release stroke of the hydraulic cushion: | |

| ca. 10 mm | |

| Locking rate: | 80 mm/sec. |

| Max. Operating temp | 70°C |

* Alternative plug connections on request

Advantages

- Securing the slide in any position

- Press overload independent

- Electrical control of all important functions

- Compact dimensions

- Central control

- One-motor operation

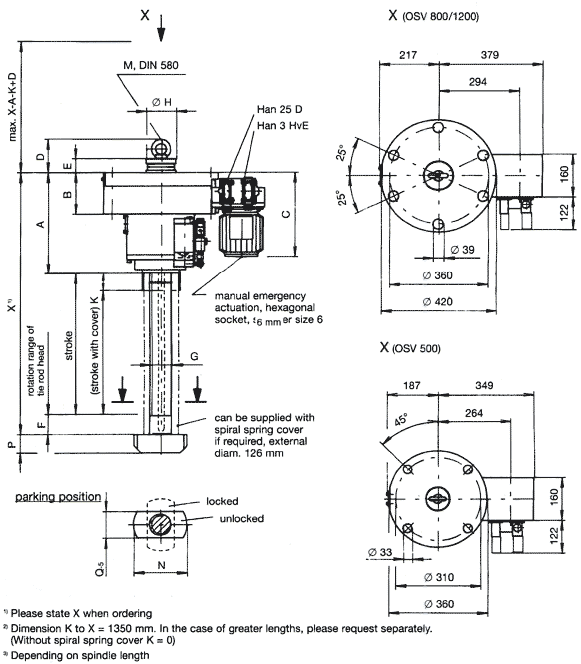

Construction

The slide lock system has a forged chromium-molybdenum steel tie rod.

To secure the machine, please use four bolts strength class 10.9 according to DIN 912 (not included). The thread dimension depends on the type.

| Type | FB (kN) |

Motor Power (kW) |

A | B | C | D | E | F | G | H | K2) | M | N | P | Q | Weight (kG) |

| OSV 500 | 500 | 0.75 | 340 | 135 | 315 | 109 | 47 | 60 | Tr60x9 | 90 | 75 | M16 | 145 | 50 | 70 | ca. 200 |

| OSV 800 | 800 | 1.5 | 380 | 155 | 325 | 124 | 52 | 75 | Tr80x10 | 110 | 100 | M20 | 195 | 70 | 100 | ca. 280 |

| OSV 1200 | 1200 | 1.5 | 380 | 155 | 325 | 124 | 52 | 75 | Tr80x10 | 110 | 100 | M20 | 195 | 70 | 100 | ca. 300 |