HDSZ

Hydraulic Turn-Clamp Cylinder

Area of application

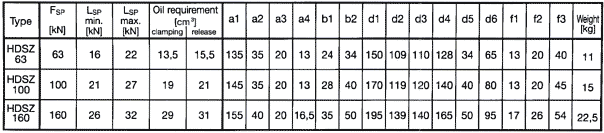

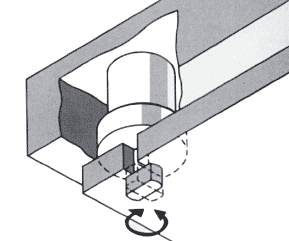

The hydraulic automatic clamp cylinder, type HDSZ is designed for medium-sized machines exerting a force of up to about 700 tons. It is mainly used for top die clamping (with and without clamping edge). For this purpose, T-slots or lock plates in the dies to be clamped are required.

Rigid fixing of the clamp cylinder in recesses in the press ram (or bed) is necessary.

The clamp cylinder places little demands on the periphery of the machine. Its control can be easily combined in the existing machine control system.

Mode of operation

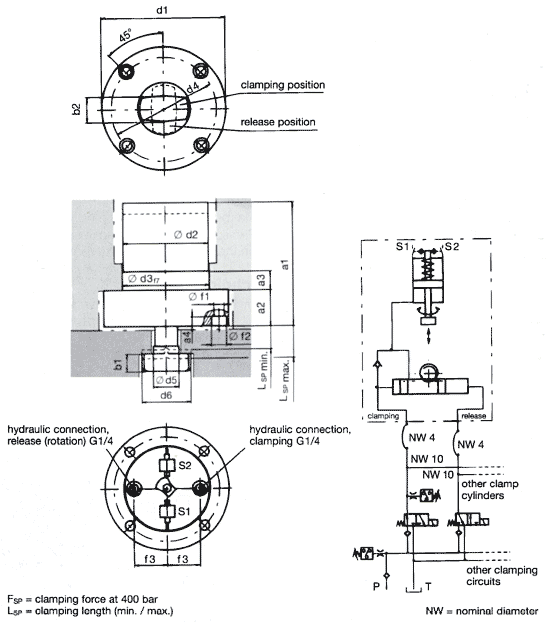

The clamping process is effected by a single-acting hydraulic cyl inder with return spring. The subsequent rotary movement of the tie rod is also effected hydraulically (2 hydraulic connections). In so doing the tie rod pinion, and hence the tie rod head, is rotated by means of a toothed rack until the clamping stroke is completed by way of an edge control boring.

Release is effected hydraulically after reversing the hydraulic valve, with the aid of a return spring and the subsequent rotation of the tie rod.

Movement sequence for applying the clamping force:

- 90° rotation

- The clamping stroke of the tie rod (release of the clamp unit in reverse order)

Distinguishing features

The hydraulically operated clamping cylinder directly produces the necessary clamping force. In so doing, the hydraulic pressure must be maintained throughout the clamping process (optional equipment with nonreturn valves and pressure switches recommended).

By installing the cylinder in recesses provided for it in the press bed, the surface of the clamp cylinder ends just below the ram surface; only the tie rod projects from the surface (also in the released position).

Electrical control of the following functions (switches):

- Tie rod released and rotated into the release position (S1)

- Tie rod rotated into clamping position (S2)

- Pressure control by means of pressure switch on the hydraulic unit is advisable

Technical data

| Switch: | 2 inductive proximity switches; p-n-p normally open contact |

| Supply voltage: | 10-30 V DC |

| Cable length: | ca. 3 m |

The clamp cylinder type HDSZ can be used for operating at temperatures of up to 70°C, and a maximum operating pressure of 400 bar.

The clamp cylinder has a manually operated emergency actuation device.

Advantages

- Completely automatic, purely hydrauliC operation

- Large clamping thickness tolerance

- Central control

- Highest safety standard due to electrical control

- Low installation cost

- Low maintenance cost

- Highest clamping force, despite compact dimensions of the clamp cylinders.

Construction

The clamp cylinder has a gunmetal-finish housing and a gunmetal-finish tie rod.

It is secured by four bolts, of strength class 10.9 according to DIN 912 (not included). The thread dimension depends on the type (see technical drawing).