Feeder Systems

GPA manufactures multi-axis, freely programmable linear-robots for the loading and unloading of single presses or the linking of press lines. Capacity ranges include:

- blanks of up to approx. 3500 mm

- feed axis of up to 1500 mm vertically and 6000 mm horizontally

- number of strokes: up to 30 strokes per minute

- up to five controlled axes

- communication (handshake) links to the press or monitoring control system

In addition, we can supply feeder tooling as well as shuttle transport systems to carry parts from feeder to feeder or from press to press.

Utilization

GPA Automation Feeder Systems can be designed to perform a multitude of tasks in and around presses. These include the loading and unloading of presses, destacking of blanks, stacking of formed parts, and press-to press parts transfer in a press line. In addition to these uses, feeders can be designed to perform various other tasks. By integrating auxiliary equipment such as transport stations, shuttles, conveyors, tooling, etc., we are able to fulfill almost every conceivable parts handling requirement.

Concept

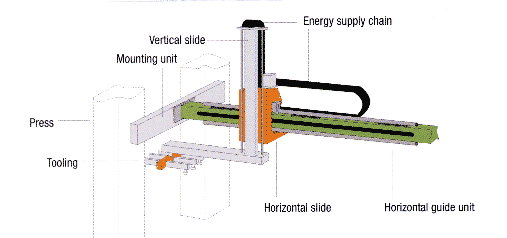

GPA Feeder Systems consist of servo-driven horizontal and vertical axes. The use of rigid aluminum extrusions with hardened steel guides and solid aluminum castings assures optimum parts positioning even in long travel and high speed applications. Our design incorporates lightweight moving components with rugged guides and drives necessary for harsh environments. Guides, bearings, etc. are tied to an automated lubrication system. Important maintenance functions are brought to the attention of service personnel via the operator panel.

A quick disconnect coupling links the feeder and part specific tooling. A freely programmable processor coordinates all servo-driven axes internal routines, tooling memory, and all critical input and output signals. The feeder is operated via a compact control panel specifically designed to be user friendly. This insures that operators quickly and precisely master the systems function and are immediately in control.

Design

Options

Almost anything is possible!

- Implementation of additional axes (overdrive system, rotation axis, tip axis)

- Integration into transfer shuttles

- Cross drives for the feeder and shuttle (easy access for quick die change)

- Integration into stackers, destackers, conveyors, palletizers

- Press to press transfers for complete press line integration

- Etc., etc., etc.

Please contact us for further ideas. We will find a solution for you!

Mounting and Integration

GPA Feeder Systems are usually bolted directly to the press uprights, regardless if they are fixed or traveling. The necessary control panels are included and usually mounted next to the press or on a mezzanine. Some instances require that the feeder be bolted to the floor or to a gantry mounted between presses.

The electrical control systems are delivered as a turn-key package. The electrical installation and connection of the control panel, feeder and operator panel is simplified through the use of power cards and multi-pin connectors. On-site requirements include power connections, press output and input signals, the signals required for auxiliary equipment (e.g. conveyors) and telephone lines for off-site modem service. The customer can choose either to build his own tooling or to order it from GPA.

All systems are tested in our factory prior to delivery. This assures fast and reliable installations in the field.

Specifications

| TYPE | AF 20 | AF 30 | AF 40 | |

| Horizontal Travel | mm | 1000/1250/1600/2000 | 1000/1250/1600/2000 2500/3000/4000 | 1000/1250/1600/2000 2500/3000/4000 |

| Vertical Travel | mm | 200-1500 | 200-1500 | 200-1500 |

| Horizontal travel speed max. without overdrive | m/sec | 4.0 | 3.6 | 2.5 |

| With overdrive | m/sec | 9.5 | 7.2 | 6.0 |

| Vertical travel speed max. | m/sec | 2.5 | 2.0 | 1.6 |

| Horizontal acceleration max. without overdirve | m/sec2 | 10 | 7 | 5 |

| With overdrive | m/sec2 | 20 | 14 | 10 |

| Vertical acceleration max. | m/sec2 | 5 | 3.8 | 2.5 |

| Part mass max. | kg | 50 | 80 | 125 |

| Part

dimension max. in/cross the transport direction given blank thickness 0.8 |

mm | 850/1200 | 1200/2000 | 2000/3500 |

| Given blank thickness 1.2 | mm | 600/1000 | 1000/1800 | 1800/3000 |

| Tooling length max. given blank thickness 0.8 | mm | 1000 | 1600 | 2300 |

| Given blank thickness 1.2 | mm | 800 | 1400 | 2000 |

| Positioning accuracy | mm | +-0.3 | +-0.3 | +-0.3 |